- Products

- PoE Media Converters and Switches

- Ethernet & PoE Switches Product Selector

- Multi-Gigabit Ethernet and PoE Switches

- PoE PSE Commercial Switches

- PoE PSE Industrial Fiber Switches

- PoE Industrial Copper Extenders

- PoE Powered Media Converters

- PoE PSE Media Converters

- PoE Extenders & Injectors Product Selector

- Pluggable Transceivers Product Selector

- Single Pair PoE Products

- Product Lines

- iConverter Managed Multi-service Platform

- Copper to Fiber Media Converters

- Ethernet Media Converters

- 10 Gigabit Copper-to-Fiber

- 10/100/1000 Copper to 10 Gigabit Fiber

- 10/100/1000 Copper-to-Fiber with Integrated Management

- 10/100/1000 Industrial Copper-to-Fiber with Integrated Management

- 10/100/1000 Copper-to-Fiber with VLAN

- 10/100/1000 Dual Media Converter with VLAN

- Gigabit Copper-to-Fiber

- 10/100 Copper-to-Fiber with Integrated Management

- 10/100 Industrial Copper-to-Fiber with Integrated Management

- 10/100 Copper-to-Fiber with VLAN

- 10/100 Copper-to-Fiber

- Fast Ethernet Copper-to-Fiber

- Fast Ethernet Redundant Links

- 10Mbps Copper-to-Fiber

- 10Mbps Copper to Coax

- TDM Media Converters

- Serial Media Converters

- Ethernet Media Converters

- Fiber to Fiber Media Converters

- 10 Gigabit Fiber-to-Fiber Converter and Transponder

- 10 Gigabit Industrial Converter and Transponder

- SFP-to-SFP Fiber Converter and Transponder

- SFP-to-SFP Industrial Fiber Converter and Transponder

- Gigabit Fiber to-Fiber with 3 Rs

- 100/1000 Fiber-to-Fiber with 3 Rs

- Gigabit Fiber-to-Fiber

- Fast Ethernet Fiber-to-Fiber with 3 Rs

- Fast Ethernet Fiber-to-Fiber

- OC-3/STM-1 Fiber-to-Fiber

- OC-12/STM-4 Fiber-to-Fiber

- Carrier Ethernet Network Interface Devices

- CE 2.0 - 10G Demarcation NID

- CE 2.0 - 10/100/1000 Mult-port NID

- CE 2.0 - 10/100/1000 Mult-port NID with PoE

- CE 2.0 - 10/100/1000 8-Port NID

- CE 1.0 Service OAM - 10/100/1000 NID

- CE 1.0 Link OAM - 10/100/1000 Copper-to-Fiber NID

- CE 1.0 Link OAM - 10/100 Copper-to-Fiber NID

- CE 1.0 Link OAM - Gigabit Fiber-to-Fiber NID

- CE 1.0 Link OAM - Fast Ethernet Fiber-to-Fiber NID

- CWDM Multiplexers

- T1/E1 Multiplexers

- Ethernet Switch Modules

- Management System

- Chassis Options

- 1-Module Industrial Chassis

- RuggedNet Industrial Switches and Extenders

- Industrial PoE PSE Fiber Switches

- Multi-Gigabit Managed Industrial PoE+/BT Switches

- Multi-Gigabit Unmanaged Industrial PoE+/BT Switches

- 10G Managed 802.3bt PoE Switches

- 10G Unmanaged 802.3bt PoE Switches

- 10G Managed PoE+ Switches

- 10G Unmanaged PoE+ Switches

- 1G Managed PoE+ Switches

- 1G Unmanaged PoE+ Switches

- 1G Unmanaged 802.3bt PoE Switches

- 1G Managed 802.3bt PoE Switches

- Industrial SPE Switches

- Industrial Ethernet Switches

- Industrial PoE Copper Extenders

- Industrial Power Supplies

- OmniConverter Media Converter, Switches and Extenders

- PoE PSE Media Converters

- 10G Multi-Gigabit / Multi-Rate PoE Media Converter

- 10G Multi-Gigabit / Multi-Rate Media Converter

- 10/100 Multi-port PoE+ Media Converter

- 10/100 PoE+ Media Converter

- 10/100/1000 Multi-Port PoE+ Media Converter

- Industrial 10/100/1000 Multi-Port PoE+ Media Converter

- 10/100/1000 PoE+ Media Converter

- 10/100/1000 PoE++ 60W-100W Media Converter

- Industrial 10/100 Multi-port PoE+ Media Converter

- 1U Rack-Mount Shelf

- PoE PSE Compact Switches

- Multi-Gigabit Managed PoE+/BT Switches

- Multi-Gigabit Unmanaged PoE+/BT Switches

- 10G Managed 802.3bt PoE Switches

- 10G Unmanaged 802.3bt PoE Switches

- 10G Managed PoE+ Switches

- 10G Unmanaged PoE+ Switches

- 1G Managed PoE+ Switches

- 1G Unmanaged PoE+ Switches

- 1G Managed 802.3bt PoE Switches

- 1G Unmanaged 802.3bt PoE Switches

- Ethernet Switches

- Single Pair Ethernet (SPE)

- PoE Copper Extenders

- PoE Injectors

- miConverter Unmanaged Miniature Media Converters

- 10/100/1000 Copper-to-Fiber

- Industrial 10/100/1000 Copper-to-Fiber

- 10/100/1000 Ultra-Compact Copper-to-Fiber

- Gigabit Copper-to-Fiber

- 10/100/1000 Copper-to-Fiber PoE Powered

- 10/100 Copper-to-Fiber

- 10/100 Ultra-Compact Copper-to-Fiber

- 10/100 Copper-to-Fiber PoE Powered

- 18-Module Chassis

- Industrial 10/100 Copper-to-Fiber PoE Powered

- FlexSwitch Compact Switches

- Solutions

- Company

- Support

- How to Buy

Omnitron Industrial Ethernet Switches Overview

Omnitron Industrial Ethernet Switches are a range of high-performance, ruggedized switches designed for demanding industrial environments. These industrial switches offer a wide range of features, including:

- Rugged and reliable construction: Omnitron Industrial Ethernet Switches are crafted to endure extreme industrial environments. They are IP40-rated for dust and moisture protection and can operate within a temperature range spanning from -40°C to 75°C (- 40°F to 167°F).

- Fast and reliable connectivity: Omnitron Industrial Ethernet Switches provide high-speed Ethernet connectivity up to 10Gbps. They support various network protocols, including VLAN, QoS, and Link Layer Discovery Protocol (LLDP).

- Power over Ethernet (PoE): Omnitron Industrial Ethernet Switches support PoE to power connected devices such as IP cameras, wireless access points, and industrial controllers.

- Flexible deployment options: Omnitron Industrial Ethernet Switches are available in various form factors, including wall-mount, rack-mount, and DIN-rail mounting. They can be managed remotely using a web interface, Telnet, SSH, SNMP, or serial console.

|

Models |

Ports |

Management |

PoE Port |

Data Rate |

|---|---|---|---|---|

|

Two 100M/1G/2.5G/5G/10G copper user ports. Two 10/100/1000 copper user ports. 1G/10 SFP/SFP+ transceiver uplink or 100M/1G/2.5G/5G/10G RJ-45 uplink |

Unmanaged |

- |

Multi-Gigabit / Multi-Rate |

|

|

Eight or four10/100/1000 copper user ports Two 1/10G SFP/SFP+ transceiver uplink ports |

Managed |

- |

10G |

|

|

Eight or four 10/100/1000 copper user ports Two 10/100/1000 copper or Gigabit fiber uplink ports |

Managed |

- |

1G |

|

|

Eight or four 10/100/1000 copper ports Two 1/10G SFP/SFP+ transceiver uplink ports |

Unmanaged |

- |

10G |

|

|

Eight or four 10/100/1000 copper user ports Two 10/100/1000 copper or Gigabit fiber uplink ports |

Unmanaged |

- |

1G |

|

|

Two 100M/1G/2.5G/5G/10G copper PoE++ user ports. Two 10/100/1000 copper PoE++ user ports. 1G/10 SFP/SFP+ transceiver uplink or 100M/1G/2.5G/5G/10G RJ-45 uplink |

Unmanaged |

4 x PoE++ (60W-100W) |

|

|

|

Two 100M/1G/2.5G/5G/10G copper PoE+ user ports. Two 10/100/1000 copper PoE+ user ports. 1G/10 SFP/SFP+ transceiver uplink or 100M/1G/2.5G/5G/10G RJ-45 uplink |

Unmanaged |

4 x PoE/PoE+ |

Multi-Gigabit / Multi-Rate |

|

|

Four or eight 10/100/1000 copper PoE user ports Two 1/10G SFP/SFP+ transceiver uplink ports |

Managed |

8 × PoE/PoE+ |

10G |

|

|

Four 10/100/1000 copper PoE user ports Two 1/10G SFP/SFP+ transceiver uplink ports |

Managed |

4 × PoE++ (60W-100W) |

10G |

|

|

Four or eight 10/100/1000 copper PoE+ user ports Two 10/100/1000 copper or Gigabit fiber uplink ports |

Managed |

8 × PoE/PoE+ |

1G |

|

|

Four 10/100/1000 copper PoE user ports Two 10/100/1000 copper or Gigabit fiber uplink ports |

Managed |

4 × PoE++ (60W-100W) |

1G |

|

|

Four or eight 10/100/1000 copper PoE/PoE+ ports Two 1/10G SFP/SFP+ transceiver uplink ports |

Unmanaged |

8 × PoE/PoE+ |

10G |

|

|

Four 10/100/1000 copper PoE ports Two 1/10G SFP/SFP+ transceiver uplink ports |

Unmanaged |

4 × PoE++ (60W-100W) |

10G |

|

|

Four or eight 10/100/1000 copper PoE/PoE+ user ports Fiber or copper uplink ports |

Unmanaged |

8 × PoE/PoE+ |

1G |

|

|

Four 10/100/1000 copper PoE user ports Two 10/100/1000 copper or Gigabit fiber uplink ports |

Unmanaged |

4 × PoE++ |

1G |

How Industrial Ethernet Switch Works?

Industrial Ethernet switches operate on the principles of packet switching, which is a method of data transmission that breaks up data into small packets and forwards them to their destination through the most efficient path. This contrasts with traditional Ethernet hub setups, where all devices on the network share the same bandwidth, leading to congestion and performance issues.

When a device connected to the industrial switch sends data, the switch's MAC address filtering mechanism analyzes the data packet's destination MAC address. This unique identifier is assigned to each device on the network, allowing the switch to determine which port to forward the packet to. Once the destination port is identified, the switch replicates the packet and sends it to the appropriate device.

Omnitron Industrial Ethernet Switches Applications

Common applications for Omnitron Industrial Ethernet Switches include:

- Industrial automation: Omnitron Industrial Ethernet Switches are used to connect industrial devices such as PLCs, HMIs, and motor drives.

- Manufacturing automation: Omnitron Industrial Ethernet Switches are used to connect manufacturing equipment such as robots, conveyor belts, and CNC machines.

- Utility networks: Omnitron Industrial Ethernet Switches are used to connect smart grid devices such as meters, sensors, and control systems.

- Transportation networks: Omnitron Industrial Ethernet Switches are used to connect railway signaling systems, intelligent intersections, smart parking, traffic management systems, and passenger information displays.

- Security networks: Omnitron’s Industrial Ethernet PoE switches provide connectivity and PoE power to IP surveillance cameras in a variety of outdoor settings.

- Wireless networks: Omnitron Industrial PoE switches provide reliable connectivity to WiFi access points, small cells and other PoE-powered IoT devices

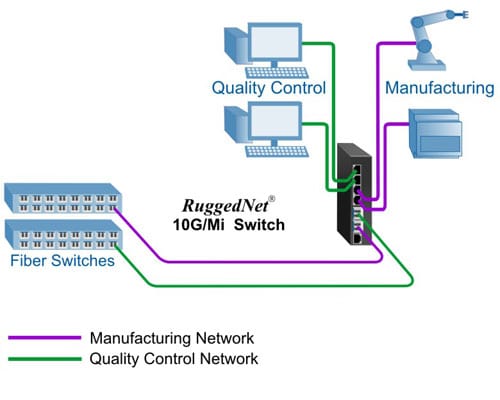

Dual Device Mode Application

Omnitron industrial switches support Dual Device mode, an advanced feature that enables the switch to operate as two independent and isolated Ethernet switches. This is useful when two distinct network domains share a single network distribution location.

The application below demonstrates a scenario where the quality control and manufacturing networks share a single hub distribution location. Using the two uplinks and the Dual Switch mode facilitates using a single industrial switch driving the Quality Control and the Manufacturing devices while maintaining isolation between the networks.

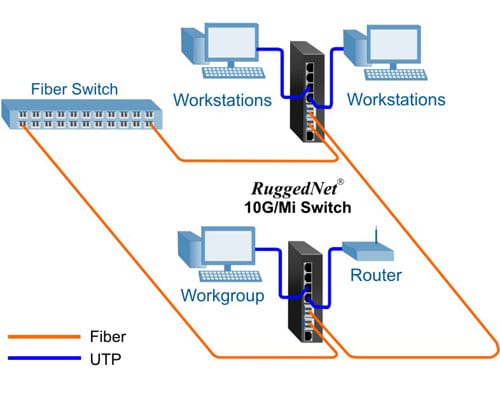

Daisy-Chain and Ring Topology Network Application

This application demonstrates the daisy chaining and ring capabilities of the industrial switches. In this application, each RuggedNet switch establishes a connection with its neighboring switches through its uplink ports, eventually closing the ring. The RuggedNet industrial switches provide connectivity between the workstations and the router.

This network architecture, combined with ring protection protocols such as Media Redundancy Protocol (MRP) or Rapid Spanning Tree Protocol (RSTP), facilitates a highly resilient network required in mission-critical applications.

Omnitron Managed Industrial Ethernet Switches

RuggedNet managed Ethernet and PoE switches have a built-in web interface that can be viewed through most web browsers.

Omnitron’s Ethernet and PoE switches can be remotely configured using the IP-based web management interface. The IP-based web management can be accessed through any of the Ethernet RJ-45 or uplink ports and facilitates the configuration and real-time operation monitoring of each port.

The web management software provides intuitive and easy-to navigate menu options, and assists network managers with:

- Remote Configuration and Monitoring

- Detailed PoE Port Status

- Smart PD alive heartbeat check

- Individual port PoE power reset

- PoE power scheduling for security and energy saving

- Text and Email Notifications

- Easy firmware updates

Conclusion

Omnitron Industrial Ethernet Switches offer a compelling combination of reliability, cost-effectiveness, and ease of management, making them the perfect option for demanding industrial environments. Their rugged construction, extended lifespan, and user-friendly management features ensure uninterrupted network connectivity, contributing to greater efficiency and profitability for businesses across various industries. If you are looking for a high-performance, ruggedized Ethernet switch for your industrial network, consider Omnitron Industrial Ethernet Switches. Call us now to get pre-sale support.